Product Details

Place of Origin: Shandong China

Brand Name: silk

Certification: ISO TUV SGS BIS CE

Model Number: DX51D SGCC SGCD SGCE DX52D

Payment & Shipping Terms

Minimum Order Quantity: 3Tons

Price: Negotiable

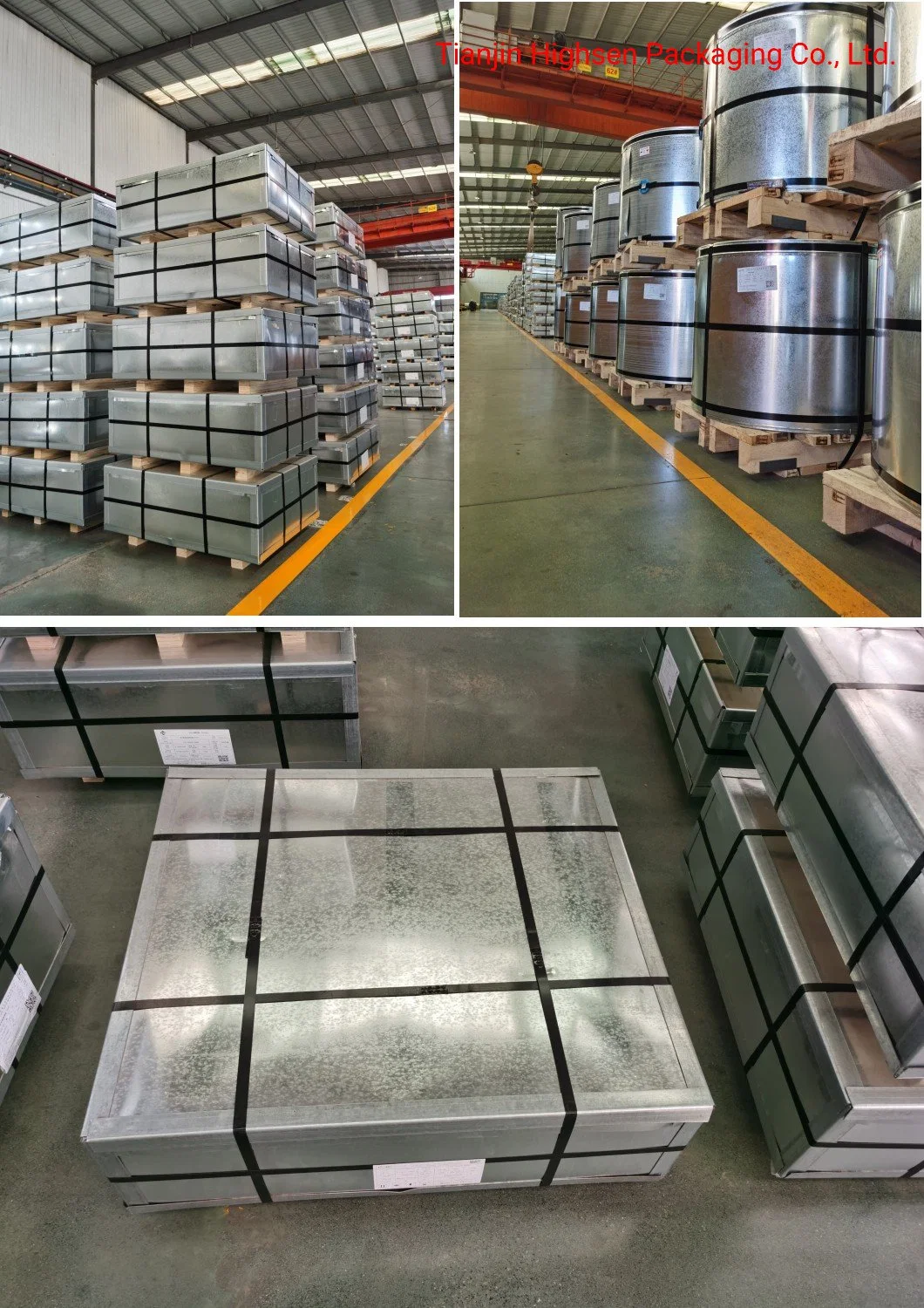

Packaging Details: With iron sheet to pack the steel sheet and pallet .Also make the shipping marks on each bundles.

Delivery Time: 5-15days depend on the quantity

Payment Terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram,OA

Supply Ability: 5000Tons Per Months

Product Name: |

Galvanized Roofing Sheet |

Standard: |

EN10202, JIS G3303, ASTM A623/ A624/ A625/ A626 |

Material: |

MR, SPCC |

Thickness: |

0.14 - 0.50mm |

Width: |

600 - 1050mm |

Temper: |

T1, T2, T2.5, T3, T3.5, T4, T5, DR7, DR8, DR8M, DR9, DR9M, DR10 |

Coating For TFS: |

Metal Chromium Layer: 50-150mg/m2, Chromium Oxide Layer: 5-35 Mg/m2 |

Post Treatment: |

Passivation, Dos Oil |

Processing Service: |

Cut To Sheet, Scroll Cut, Lacquer And Print Service |

Application: |

General Line Packaging |

Product Name: |

Galvanized Roofing Sheet |

Standard: |

EN10202, JIS G3303, ASTM A623/ A624/ A625/ A626 |

Material: |

MR, SPCC |

Thickness: |

0.14 - 0.50mm |

Width: |

600 - 1050mm |

Temper: |

T1, T2, T2.5, T3, T3.5, T4, T5, DR7, DR8, DR8M, DR9, DR9M, DR10 |

Coating For TFS: |

Metal Chromium Layer: 50-150mg/m2, Chromium Oxide Layer: 5-35 Mg/m2 |

Post Treatment: |

Passivation, Dos Oil |

Processing Service: |

Cut To Sheet, Scroll Cut, Lacquer And Print Service |

Application: |

General Line Packaging |

|

Thickness

|

0.14 - 0.50mm

|

||

|

Width

|

600 - 1050mm

|

||

|

Length

|

As per customer requirement

|

||

|

Steel Type

|

MR, SPCC

|

||

|

Annealing

|

BA (Batch Annealed), CA (Continuously Annealed)

|

||

|

Standard

|

EN10202, JIS G3303, ASTM A623/ A624/ A625/ A626

|

||

|

Temper

|

T1, T2, T2.5, T3, T3.5, T4, T5, DR7, DR8, DR8M, DR9, DR9M, DR10

|

||

|

Coating for ETP

|

Euqally coated (1.1/1.1, 2.0/2.0/ 2.8/2.8/ 5.6/5.6, 8.4/8.4, 11.2/ 11.2)

Differetially coated (2.0/1.1, 2.8/1.1, 5.6/1.1, 5.6/2.8, 8.4/2.8, 8.4/5.6, 11.2/2.8, 11.2/5.6, 11.2/8.4, 15.1/5.6) |

||

|

Coating for TFS

|

Metal Chromium Layer: 50-150mg/m2, Chromium Oxide Layer: 5-35 mg/m2

|

||

|

Delivery time

|

20-45 days

|

||

|

Supply Capacity

|

8,000MT per month

|

||

|

Shape

|

Coil, Sheet

|

|

Coil ID

|

420mm or 508mm

|

|

Coil Weight

|

3-8MT or 6-12MT

|

|

Bundle Weight

|

2MT Max

|

|

Surface

|

Bright, Stone, Fine Stone, Sliver, Matt

|

|

Post treatment

|

Passivation, Dos Oil

|

|

Processing service

|

Cut to sheet, scroll cut, lacquer and print service

|

|

Application

|

A. Food Cans (Beverage Cans, Milk Cans, Fruit Cans, Tomato Cans, Edible oil etc. )

B. Industrial Cans (Paint Cans, Chemical Cans, Lube containers) C. General Line Packaging (Aerosol Can, Gift Cans, Cookies Cans, Stationery Box etc.) |

|

MOQ

|

25MT per size

|

|

Delivery Tolerance

|

+/-10%

|

|

Packing

|

Standard seaworthy export packing (horizontal or vertical)

|

Type of Steel

| MR | It contains few residual minor constituents and has good corrosion resistance. It is widely used for the applications of containers. |

||||

| L | It contains particularly few residual minor constituents as Cu, Ni, Cr, Mn. It is suitable for the materials of containers requiring improved corrosion resistance. |

||||

| D | It is an aluminum killed steel. It is suitable for the applications, that bear deep drawing or other workings which may produce Luder's lines patterns. |

||||

Surface finish

| Product finish | Steel base | Product | Flow-melted | Surface roughness | Remark |

| Ra (μm) | |||||

| Bright | smooth | Tinplate | Yes | ≤ 0.35 | Note 1: Double reduced product is only supplied as stone finish. Note 2: Sub-classfied based on the surface finishing of the blackplate. Note 3: The appearance is governed by: a) the surface characteristics of the steel base which principally result from controlled preparation of the work rolls used during the final stages of temper rolling; b) the mass of the coating applied; and c) whether the tin layer is flow-melted or unflow-melted. |

| Fine stone | fine stone | Tinplate | Yes | 0.25 - 0.45 | |

| Stone | stone | Tinplate | Yes | 0.35 - 0.60 | |

| Silver | shot blast | Tinplate | Yes | ≥ 0.90 | |

| Matt | shot blast | Tinplate | No | Various | |

| Fine stone | fine stone | TFS/ ECCS | - | 0.25 - 0.45 | |

| Stone | stone | TFS/ ECCS | - | 0.35 - 0.60 |

FAQ: